Infra-red Interferometry

Interferometry is used as a routine test for optical components and

systems at wavelengths ranging from the visible to above 10 microns. In

the infra-red the main wavebands used are from 3 to 5 microns and from 8

to 12 microns. Typical laser sources used are HeNe (3.39microns) and

HeXe (3.49 microns) in the shorter waveband and CO2 (10.6 microns or

tuneable) in the longer waveband. Infra-red interferometry presents some

problems which require that special care is taken in the setting up of

the measurement, and that the results are analysed in as rigorous a

manner as possible.

Infra-red optical

systems are being produced with smaller optical apertures than

previously for reasons of weight, cost and configurability. This trend

has been aided by improvements in the detector technology. The result is

that the IR lens for a camera system may have an aperture comparable in

size to a visible camera system. However the wavelength in the IR system

may be as much as twenty times greater than in the visible band. This

makes the effects of diffraction much more dominant in IR

interferometry, requiring that optical pupils are well focused onto the

interferometerās camera sensor surface. Because of the double pass

nature of most commercially available interferometers the aperture is

Īseenā twice by the interferometer - if the two images of the

optical aperture are not conjugate with one another then some

diffraction is inevitable. The effects of this must be minimised to

enable accurate analysis.

Figure 1 shows

two ways of analysing a lens with an interferometer. One test uses a

spherical reference mirror while the other uses a flat reference mirror

but requires an additional high quality focusing lens (or reference

sphere) in order to make the measurement. From the point of view of

diffraction the measurement using the reference sphere is preferred,

since the return mirror can be very close to the pupil of the lens under

test, therefore the pupil and its image via the mirror can both be very

close to focus on the interferometers camera faceplate. This is not

possible using the other arrangement, diffraction will be present

especially if the spherical mirror radius is small so that it is

physically far from the lens under test. Many tests in the infra-red use

high grade ball bearings as return mirror ö it is important that any

analysis of the interferograms takes into account the limitations of the

method.

|

|

Figure

1. Reflection Configurations

|

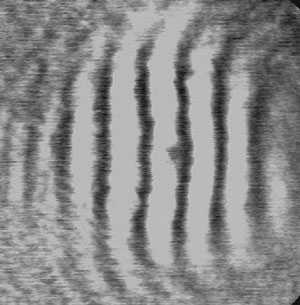

Figure 2 shows the effect of diffraction on the pupil imagery in

the interferometer.

|

|

|

| Focused

Pupil |

Unfocused

Pupil |

|

Figure

2. Pupil Imagery

|

In the unfocused

case, diffraction rings can clearly be seen inside the pupil. This has

the effect of breaking up the interference pattern such that the fringes

are discontinuous or vary in width due to contrast changes. Any

automatic fringe analysis program must be used with caution when

analysing such fringes. In general the peak to valley wavefront

aberration reported will be worse than the actual for the lens under

test.

While figure 2 shows

the effect of diffraction within the optical pupil, the other common

case is when the diffracted radiation appears outside the pupil. This

has the effect of blurring the pupil edge so its size is uncertain and,

because the diffracted radiation has a different curvature to the main

beam, any interference fringes will curve within this zone. The effect

is very similar to that seen with Spherical Aberration especially that

of higher order and if not corrected can lead to a large departure in

measured vs. actual performance. This situation is shown schematically

in Figure 3.

|

|

|

|

Focused

Pupil

|

Unfocused

Pupil

|

|

Figure

3. Pupil Imagery Effects on Fringes

|

In this case, if information is known

about the size of the pupil within the interferogram, it is

possible to mask out much of the effects of diffraction simply by

ignoring those parts outside the pupil.

There will be cases

where it is impossible to achieve good pupil imagery without going to

great expense. In such circumstances, double pass interferometry can

still provide a confidence test on system performance, but ultimate

proof may require a single pass test, either by interferometry or by non

coherent broad band MTF testing or similar.

Infra-red

interferometry relies on sensing using an Infra-red camera, either

staring array CMT or a Pyroelectric vidicon tube. The latter is the most

used, mainly because of the cost of the camera. The cameras exhibit

random noise on the video signal. this is most obvious in the 3 to 5

micron waveband, where available, affordable lasers tend to be of low

power (typically 5-10mWatts). High signal gain is required to provide

sufficient contrast for recording fringe patterns or analysing fringe

patterns using either static or phase shifting software. Also of

relevance when laser power is marginal is the profile of the laser beam.

As much of the beam as possible must be used to maximise contrast but

this does mean that, due to the profile, the contrast varies across the

interferogram. This is particularly noticeable when using HeNe lasers at

3.39microns where perhaps only 5 to 10mWatts of power is available. This

can have the effect of making fringes appear both fainter and thinner

towards the edge of the pupil. When analysing with static fringe

analysis packages care needs to be taken to check that the digitised

fringes accurately represent the real shape of the fringe pattern.

The problems raised

by laser power profiles is greater when using Phase Shifting systems.

Phase shifting system involve a threshold contrast below which phase

will not be measured. This normally shows as a blank space in the

resulting phase map. This can be remedied by reducing the threshold.

However, using Pyroelectric vidicons with marginal laser power

represents a very noisy environment. Reducing the threshold too far mean

that the system can pick up on random noise in the picture and allocate

phase values which significantly larger than any other area of the

pupil. This has the effect of a gross distortion of the results. A

fine balance needs to be trodden between these two situations such that

phase information is available over the whole pupil without random noise

causing a problem. Generally with 3.39 micron systems, the threshold

needs to be set at around 2.5% to 3.5%.

At 10,6 microns,

these problems donāt occur. The main problem in the upper IR waveband

is finding ways of dumping excess energy ö normally with CaF2 filters

though with tuneable systems a wire grid polariser is necessary. This

means that the central part of the beam can be used ensuring a much

flatter profile, and sufficient power can be allowed through in order to

enable the pyroelectric vidicon camera to be set to low gain, thereby

reducing noise to an insignificant level. Further development in compact

high quality 3-5 micron lasers is eagerly anticipated.

|