Diffractive Optics

Athermalize IR Systems

The properties of materials employed in infrared lenses generally

exhibit significant variations with changes in ambient temperature. As a

result, the control of thermally induced degradation in image quality is

an important issue in optical systems operating at infrared wavelengths.

These include the objective lenses of thermal imagers and the optics

employed in CO2 laser-machining systems.

Precision-Optical Engineering

in Hitchin, Hertfordshire, England, has developed hybrid

refractive-diffractive lenses for passive athermalization of the optical

components of thermal imagers. They are generally in the form of a

conventional aspheric lens with a blazed zone plate diffractive

structure superimposed on the non-spherical surface. Development of room

temperature staring-array sensors operating over the 8 to 14um range

offers the potential of lightweight, low-cost and compact thermal

imagers. This requires optical systems that emphasize a given level of

performance with the minimum number of elements.

The typical lens system

comprises two germanium elements, the front one being an asphere in a

Petzval-type arrangement. This type of lens maintains acceptable optical

performance over a range of a few degrees Celsius about the ambient,

though the lens may be required to perform over -20 to +40 'C.

Typically, this discrepancy is accommodated by manual adjustment of the

focus. Precision-Optical Engineering has developed an athermalized

version of this Petzval-type lens that maintains lens performance over

the full operating temperature range.

This component replaces the

front germanium aspheric element with a doublet that comprises a

negative germanium hybrid element and a positive spherical AMTIR or zinc

Selenide component. While the lens doublet stabilizes operation over a

wide temperature range, the diffractive surface controls the resulting

primary longitudinal chromatic aberration, a particularly important

consideration in this design. Although secondary spectrum is typically

larger in hybrid lens systems than in equivalent conventional designs,

the germanium AMTIR doublet results in a very small level of this

aberration, and near-diffraction-limited performance can be achieved

on-axis. A similar hybrid solution not employing a diffractive surface

would require an additional lens material and therefore four lens

elements.

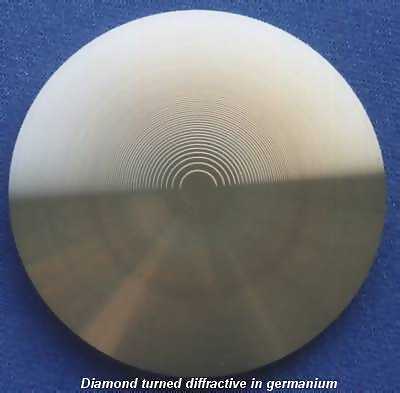

The diffractive surface

contains about 25 zones over a diameter of 75 mm and can be readily

manufactured with high diffraction efficiency by single-point diamond

turning, according to Precision-Optical Engineering. The performance of

such a lens has been assessed in the laboratory over the full operating

temperature range and matches well with theoretical predictions.

The thermal focus shift

introduced into lenses by high-power CO2 laser-machining operations can

also significantly degrade system performance. Precision-Optical

Engineering uses a diffractive surface in this case to directly cancel

the thermal defocus introduced by a conventional refractive lens. The

result is a diffractive structure with many more zones (100 to 200) than

are typically required in hybrid optics employed for the correction of

chromatic aberrations.

Reprinted from the February

1995 issue of PHOTON lCS SPECTRA © Laurin Publishing Co., Inc.

|